Vinyl Bromide

Vinyl Bromide Specification

- Smell

- Sweet, ether-like odor

- Molecular Formula

- C2H3Br

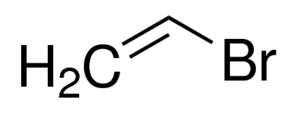

- Structural Formula

- CH2=CHBr

- Molecular Weight

- 106.95 g/mol

- Boiling point

- 15.8C

- HS Code

- 29038990

- Refractive Rate

- 1.4364 (as liquid)

- Taste

- Odorless (no taste)

- Classification

- Organic Acid Types

- Vinyl Halide

- Grade

- Industrial Grade

- Purity

- 98%

- Application

- Industrial

- Appearance

- Colorless Gas

- CAS No

- 593-60-2

- EINECS No

- 209-797-8

- Other Names

- Bromethylene; Bromoethene

- Usage

- Used as an intermediate for organic synthesis and in the manufacture of pharmaceuticals

- Melting Point

- -138C

- Density

- 1.516 Gram per cubic centimeter(g/cm3)

- Solubility

- Insoluble in water; soluble in ether and alcohol

- Raw Material

- Ethylene, Bromine

- NFPA Ratings

- Health: 3; Flammability: 4; Instability: 2

- Regulatory Status

- Subject to TSCA, REACH, and GHS regulations

- UN Number

- 1085

- Shelf Life

- 24 Months

- Handling Precautions

- Use only with adequate ventilation. Avoid inhalation and contact with skin or eyes.

- Flash Point

- Not applicable (gas at room temperature)

- Autoignition Temperature

- 455°C

- Vapor Pressure

- 1090 mmHg (20°C)

- Stability

- Stable under recommended storage conditions

- Synonyms

- Bromoethene, Ethylene bromide

- Hazard Class

- Class 2.3 (Toxic Gas)

- Packaging

- Supplied in steel cylinders or specialized gas containers

- Storage Conditions

- Store in a tightly closed container in a cool, dry, and well-ventilated area away from sources of ignition

Vinyl Bromide Trade Information

- FOB Port

- Mumbai

- Main Domestic Market

- All India

About Vinyl Bromide

With an aim to become a famous entity in this domain, we have been instrumental in offering premium grade Vinyl Bromide. The offered product is processed using quality assured chemicals by our skilled professionals with the aid of pioneering methodology. This product finds its usefulness in chemical, food processing and agriculture industries. Apart from this, the provided Vinyl Bromide can be bought from us at cost effective rates.

Key Points:

- Precise pH value

- Longer shelf life

- Optimal chemical properties

- Accurate composition

Vinyl Bromide

| Synonyms | (bromoethylene) |

| Molecular Formula | H2C=CHBr |

| Molecular Weight | 106.96 |

| CAS | 593-60-2 |

| Assay | 98% |

| Density | 1.517 |

| Comments | Melting Point (C): -139 Boiling Point (C): 16 / 750 Refractive Index: 1.4350 Flash Point (F): NONE |

Stable and Controlled Storage

Vinyl Bromide should be stored in tightly closed containers, kept cool, dry, and well-ventilated, away from ignition sources. Stable when stored correctly, this ensures product quality and safety for up to 24 months, minimizing hazard under its Class 2.3 (Toxic Gas) rating.

Industrial and Pharmaceutical Applications

Essential in industrial processes, Vinyl Bromide is primarily used as a chemical intermediate in organic synthesis and the production of pharmaceuticals. Thanks to its high purity and unique chemical properties, it is a valuable raw material in large-scale manufacturing.

Handling and Regulatory Compliance

Safe handling of Vinyl Bromide requires adequate ventilation and strict avoidance of inhalation and skin contact. As a regulated substance, it is managed under TSCA, REACH, and GHS guidelines, demanding compliance for storage, transportation, and use.

FAQs of Vinyl Bromide:

Q: How should Vinyl Bromide be stored to maintain stability and safety?

A: Vinyl Bromide must be kept in tightly closed containers in a cool, dry, and well-ventilated area, away from any sources of ignition. Proper storage helps ensure its stability, safety, and maintains product quality throughout its 24-month shelf life.Q: What are the primary uses of Vinyl Bromide in industry?

A: Vinyl Bromide is mainly used as an intermediate in organic synthesis, particularly in the manufacture of pharmaceuticals. Its unique reactivity also makes it valuable in various chemical and industrial production processes.Q: When is special handling or personal protection necessary for Vinyl Bromide?

A: Special handling is required whenever working with Vinyl Bromide due to its classification as a toxic and highly flammable gas. Use only with adequate ventilation and always avoid inhalation or contact with skin and eyes to minimize health risks.Q: Where is Vinyl Bromide typically supplied from and in what packaging?

A: Vinyl Bromide is commonly exported, manufactured, and supplied from India. It is distributed in steel cylinders or specialized gas containers designed for safe storage and transportation of toxic gases.Q: What is the process for using Vinyl Bromide as a chemical intermediate?

A: In industrial settings, Vinyl Bromide is introduced into organic synthesis reactions to form more complex molecules, particularly for pharmaceuticals. Due to its reactivity, it should be handled in controlled environments under strict safety protocols.Q: How does using Vinyl Bromide benefit organic synthesis and manufacturing?

A: Vinyl Bromides high purity and reactive nature make it an efficient choice for creating advanced intermediates in organic synthesis. This enables faster, high-yield production of complex chemicals, offering significant benefits to pharmaceutical and manufacturing industries.Q: What regulatory measures must be followed when handling Vinyl Bromide?

A: Vinyl Bromide is regulated under TSCA, REACH, and GHS. Compliance with these standards is required for storage, handling, and transportation, ensuring environmental safety and worker protection throughout its lifecycle.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry